CSR

Sustainable in everything we do

Every year we put almost 1 million items of professional clothing onto the market. Each item of clothing is made with respect for people, the environment and society.

For Sarco, high-quality clothing also means sustainability. Sustainability is the driving force throughout our value chain: from raw material to production, from use until the end of our product´s life cycle. Already in 2016 we linked our policy to the universal sustainability objectives (the Sustainable Development Goals) of the United Nations. Our focus lies on Decent Work (SDG 8), Responsible Consumption and Production (SDG 12) and the Climate (SDG 13).1. SUSTAINABLE PRODUCTION

We guarantee complete transparency so that you can personally verify whether the products you buy are sustainable and safe, and how they are made.

We therefore pay close attention to the ecological impact of the materials from the very first step in the development process. The variety in raw materials (fibres, fabrics, dyes and finishing) is already a first choice that defines how sustainable a final product is.

- We opt for more sustainable raw materials such as recycled synthetic fibres, Tencel or other fibres that are renewable in origin. We use them only after having analysed their ecological and water footprint during the production phase.

In this way SARCO has implemented several projects in Ecogreen. Those realisations can be found here.

- We are making our production processes more efficient with regard to energy and water consumption. SARCO has a management system that constantly strives to improve the environmental performances of the key processes (ISO 14001).

- The greatest impact during the use of the clothing derives from cleaning. We recommend to our customers adapted wash programmes in order to keep the water and energy footprint as low as possible, and to guarantee the clothing a maximum service life.

- Recycling is a priority in our waste policy. We give fabric cutting wastes to local mattress producers. We also have a programme where we actively seek partnerships in order to reuse or recycle discarded clothing for the development of new products, such as insulating material or parts for the car industry.

2. SUSTAINABLE CHAIN

Sarco knows the origin and composition of each product. We understand every step in the chain. We buy 90% of the raw materials from strategic suppliers with whom we have developed a long-term relationship.

The largest purchasing categories are ´cloth´ and ´packaging material´. All Sarco cloths are 100% OEKO-TEX® certified and thus contain no harmful substances. The packaging material is composed 80% of renewable fibres from sustainably managed forests. The vast majority of the packaging is recyclable cardboard, which moreover is reused wherever possible in our logistical processes.

We call on the services of ECOVADIS. This monitoring system maps out the risks in our chain, analyses where the greatest risks lie and what corrective actions are necessary for an even more sustainable chain. In 2024, we obtained here the ´Gold´ score in the sustainability performance screening.

And the high standards we set apply not only for ourselves. All of our strategic suppliers assume responsibility via our code of conduct ´from sustainable commitment to impact´. Because only then can SARCO deliver a sustainable product to the customer, strive with its suppliers and subcontractors for respect of international conventions, as well as pay attention to the impact of their activities on people, the environment and society.

ECOVADIS is a sustainability rating platform for worldwide supply chains. Ecovadis makes it easy for purchasers to judge their suppliers on sustainability criteria.

The social and sustainability ambitions of suppliers are mapped out by means of a targeted questionnaire.

3. SUSTAINABLE WORKING ENVIRONMENT

Our organisational culture focuses on teamwork, open communication and personal development for every individual. Because our employees are the company´s most important capital.

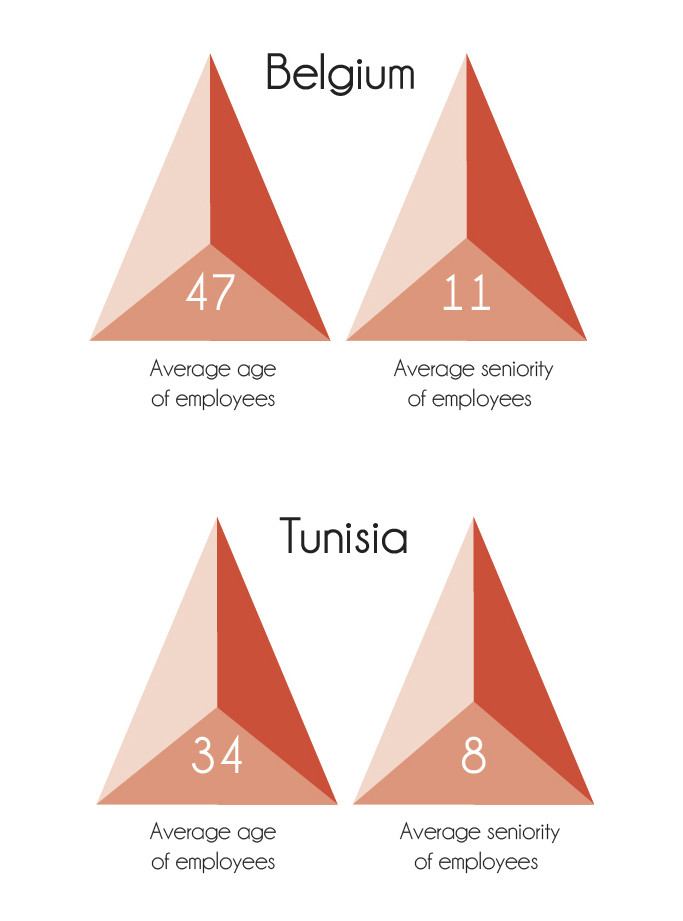

At the headquarters in Temse, a team of more than 30 professionals dedicate themselves every day to designing clothing with passion and work to continuously improve the company. And in the production site in Tunisia, more than 320 employees every day assume responsibility for the sustainable production of the clothing.

Sustainability also relates to the working conditions. SARCO invests in satisfied employees by respecting national and international labour rights, paying a decent living wage and creating safe workplaces. We are also starting programmes to promote the personal development of employees and ensure a good balance between work and private life. We also give them a high degree of autonomy with regard to organising their own work. We collaborate with local trade unions in order to continuously improve the working conditions and well-being at work. In addition, we have a whistleblowing system, so that Sarco always remains free of corruption, child labor or other abuses. You can read this policy here.

4. SUSTAINABLE LOGISTICS

Logistics is an important link in our value chain. Raw materials go to the production site in Tunisia, finished products come back to our warehouse in Temse in order to be delivered to customers in Belgium, the Netherlands and Germany.

We want to constantly reduce the CO2 footprint of our products and logistical chain. We do this by:

- Lean & Green: we choose logistical partners with an active CO2 management policy in accordance with the principles of ´lean & green´ or equivalent.

- Local suppliers: we consciously choose local suppliers. 50% of the deliveries come from within a radius of 400 km from supplier to place of delivery.

- We enter into dialogue with our customers to optimise delivery processes and ordering behaviour.

- We have invested in solar panels, thereby reducing our mains power consumption by 50%.

Lean and Green encourages and supports companies to dramatically reduce the CO2 emissions of their transport and logistics activities.

Logistical service providers undertake to improve the energy efficiency in their transport and logistics activities and to cut their CO2 emissions by at least 20% within a period of 5 years.

5. CO2 NEUTRAL

After a thorough calculation of CO2 emissions from all our processes, we managed to set up the necessary actions to further reduce our carbon footprint. We have reduced our CO2 emissions from 164.38 tonnes in 2019 to 116.71 tonnes in 2023, and our goal is to cut this by another half by 2030. Sarco has a long-term vision that focuses on using sustainable raw materials and implementing ecological production processes. Besides real climate efforts, we also guarantee support for 3 climate projects: wind energy, water energy and forest planting.